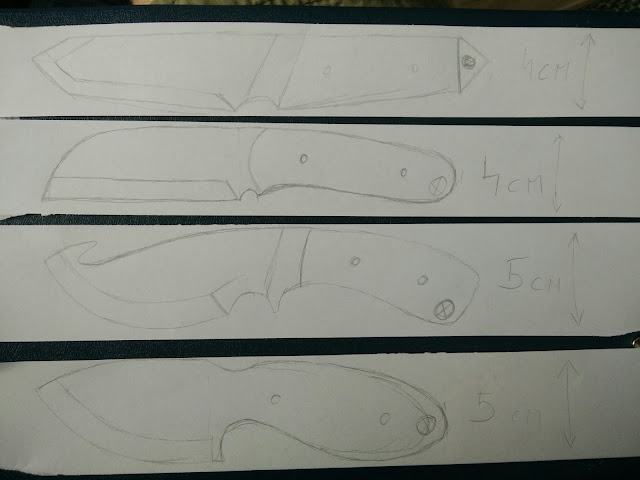

Sheepsfoot knife - making of

On Wednesday I had a few hours for my hobby :) And I had a GoPro too. The result? Please find below... Please note, this is my first video documentation of my progress. The knife currently is beveled on both sides, and that is where we are for now. Hope to find some time on this weekend to continue. Blade material: O-1 tool steel (1.2510 in the EU) 50mm wide, 3mm thick Heat treatment: My little gas forge Hardness: ~62 HRC Handle: Tropical hardwood Pins: 2mm brass rod Lanyard hole: 10mm bore Enjoy 5 At last, I had a few hours to work on the knife again. I have sanded it with p180 emery cloth and sanded the spine too. Here I had to do a short touch up with a file. I hope my video skills are getting better too :) (Part1) Enjoy 5 Unfortunately the handle material tends to break, so I had to cut it shorter. I have treated the wood with Ballistol oil, several layers. The edge is 20degrees, super sharp, cuts even the Yellow-Pages type thin paper l